OXY-COMBUSTION: WHEN BURNING WITH OXYGEN OPENS THE WAY TO RECOVERABLE CO2

A new way to burn

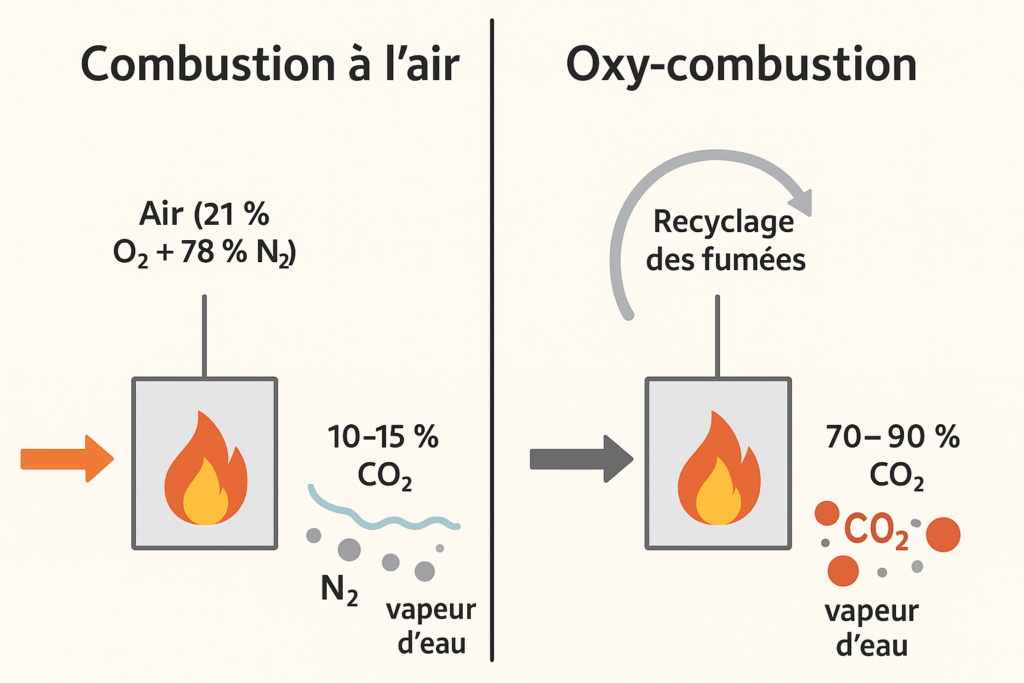

In power plants or cement factories, fuels are usually burned with air. But air is mostly nitrogen (nearly 80 %!). Result: the fumes contain little CO₂ (only 10 to 15 %).

Combustion in the presence of N2 produces nitrogen oxides, which are the source of acid pollution.

Oxy-combustion changes this pattern: instead of air, quasi-pure oxygen (95-99 %), produced in an air separation unit, is used. To prevent the flame from becoming too hot, part of the fumes already rich in CO₂ and water vapor is recycled.

As summarized by Lockwood and his colleagues in ACS Omega (2023)this principle "generates a much simpler gas stream to process, dominated by CO₂ and water vapor", notably without NOx.

The benefits of oxy-fuel combustion

- An almost nitrogen-free flue gas stream

Removing nitrogen from the equation yields gases where CO₂ accounts for 70 to 90 % of the volume (after water condensation). - Simplified capture

In conventional combustion, heavy processes are needed to separate the diluted CO₂. Here, as Toftegaard et al. in Fuel (2010)purification is much easier, which reduces the energy costs of capture". - Multi-fuel compatibility

Oxy-combustion has been tested with coal, natural gas, biomass and even cement. According to aIEA Bioenergy (2022)It is particularly promising in sectors that are difficult to decarbonize, such as cement and steel.

Opening the way to CO2 recovery

If oxy-combustion is attracting so much interest, it's not just for capturing CO₂, but also for the reuse.

A concentrated and relatively pure CO₂ stream opens the door to numerous pathways for valuation These include methanol production, the manufacture of synthetic fuels, mineral carbonation and even the feeding of microalgae cultures. As underlined by Artz et al. in Chemical Reviews (2018)CO₂ is not just a gas to be eliminated, it's a chemical resource that we need to learn how to exploit".

In other words, oxy-combustion doesn't just make capture simpler: it could become a springboard to a circular carbon economywhere yesterday's CO₂ becomes tomorrow's raw material.

With this in mind, W Platform has contributed to the development of oxy-combustion by proposing an innovative solution that accelerates its industrial integration.

Related articles

See all articles

W Platform gets a makeover

At W Platform, our mission remains the same: to capture, analyze and valorize CO₂ and other gaseous effluents in a circular economy logic. Since our inception, we've grown, matured, rethought our ambitions, and felt it was time for our image to fully reflect our current vision. That's why we're proud [...]

Supercritical CO₂: a technological lever for sustainable, high-performance extraction.

In a world seeking more environmentally-friendly industrial processes, the search for organic solvent substitutes is a daily quest for a large number of manufacturers. Among the emerging solutions, supercritical carbon dioxide (CO₂ SC) is establishing itself as a breakthrough technology in many fields, from cosmetics to [...]

W Platform awarded Young Innovative Company (JEI) status

We are proud to announce that W Platform was awarded official status as a Young Innovative Company (JEI) last May! This recognition marks a key stage in our development, and recognizes our team's constant efforts to place innovation and eco-design at the heart of our projects. Recognition of our commitment to innovation [...].

A credible alternative to 100% hydrogen for decarbonizing industrial activities

While hydrogen is often presented as the cornerstone of the energy transition, its development raises numerous technical, economic and safety challenges. A new technology, based on recycling CO₂ from combustion fumes and converting it into e-fuels like methanol, opens up a simpler, more pragmatic way of accelerating [...]

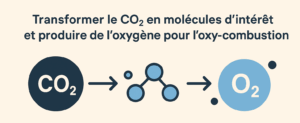

Transform CO₂ into molecules of interest and produce oxygen for oxy-fuel combustion.

Oxy-combustion is a technology that involves burning a fuel in the presence of pure oxygen, rather than using ambient air. This produces fumes containing mainly CO₂ and water vapor, making it easier to capture CO₂ for storage or recovery. However, the production of pure oxygen is energy-intensive. An alternative [...]