SUPERCRITICAL CO₂: A TECHNOLOGICAL LEVER FOR SUSTAINABLE, HIGH-PERFORMANCE EXTRACTION

In a world seeking more environmentally-friendly industrial processes, the search for organic solvent substitutes is a daily quest for a large number of manufacturers. Among the emerging solutions, supercritical carbon dioxide (CO₂ SC) is establishing itself as a breakthrough technology in many fields, from cosmetics to pharmaceuticals, food processing, chemicals and even biofuels. This "hybrid" fluid opens the way to less polluting extraction processes. But how does extraction with supercritical CO₂ actually work? That's what we're going to explore in detail.

Understanding supercritical CO₂

Supercritical CO2 is a state of matter between gas and liquid. It occurs when a substance exceeds its critical point, i.e. at least 31.1°C and 73.8 bar.

Above this threshold, CO₂ adopts unique physical properties:

- Density close to that of a liquid, enabling it to dissolve certain organic compounds,

- Viscosity and diffusivity of a gas, enabling it to penetrate to the core of solid materials.

These characteristics make supercritical CO₂ extremely effective for extracting natural molecules while being non-toxic, non-flammable and 100 % recyclable.

The supercritical CO₂ extraction process

The principle is based on bringing the material to be extracted into contact with CO₂ in its supercritical state. The process is organized in several key stages.

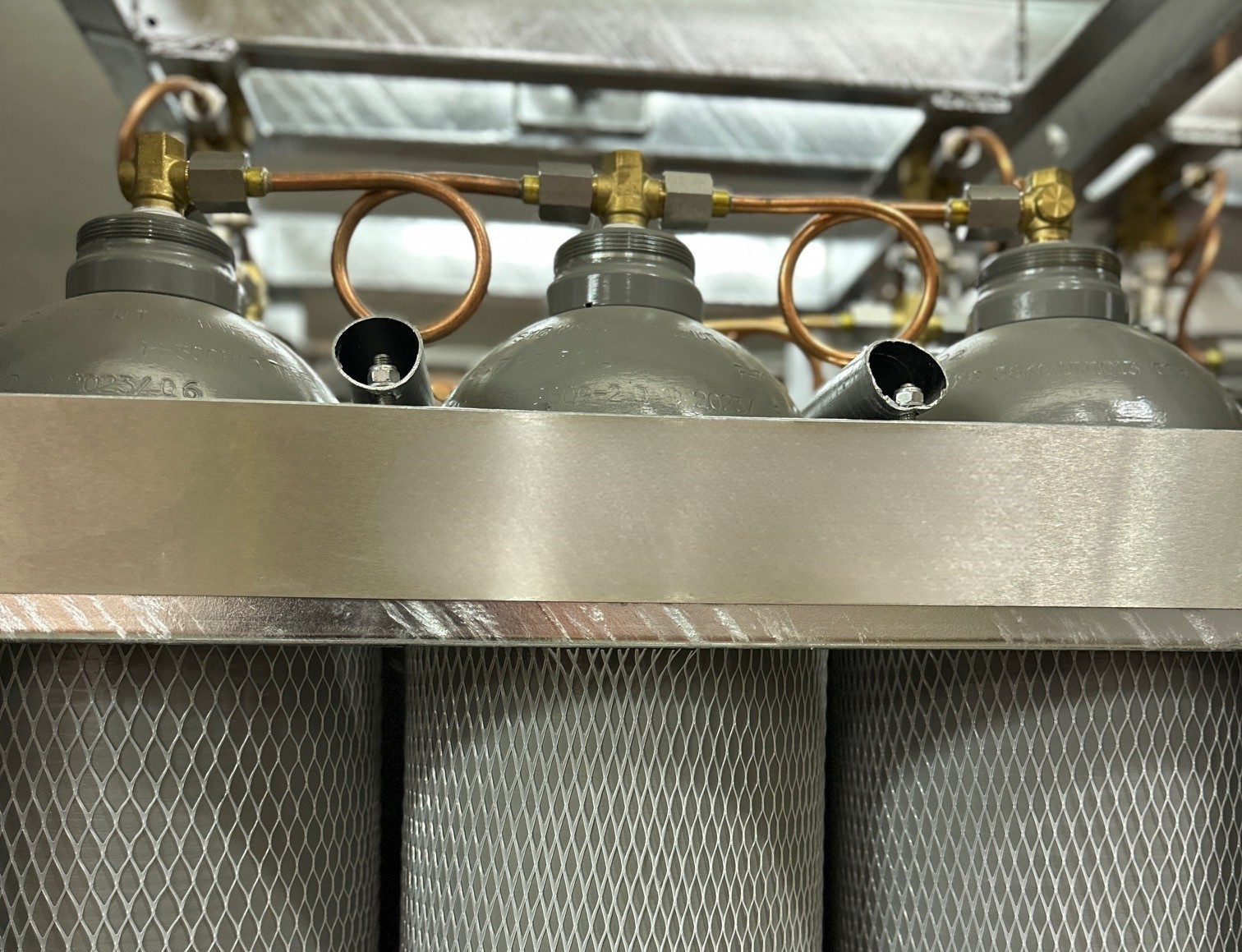

First, CO₂ conditioning, where carbon dioxide is compressed at high pressure (80 to 400 bar) and heated to the desired temperature (between 40°C and 80°C depending on the sensitivity of the molecules to be extracted).

Next, the supercritical fluid passes through the raw material contained in an extraction tank. It dissolves the targeted compounds, with adjustable precision by controlling pressure and temperature, and sometimes by adding a co-solvent to improve polarity. Finally, the mixture is decompressed in a separator. The pressure drop causes the CO₂ to revert to gas (easily recoverable and reusable), as well as the precipitation of the extracted compounds, recovered in liquid or solid form, depending on their nature. This closed-circuit system minimizes waste, reduces solvent consumption and improves overall process safety.

All supercritical CO2 extraction equipment incorporates a CO2 recycling process to limit the technology's carbon footprint when the system is depressurized. Complementary equipment enables a CO2 recycling rate of around 100% to be achieved by recovering CO2 from 50 bars at atmospheric pressure, recompressing it to 50 bars and making it available to the process.

This is what W Platform offers, with a return on investment of less than 3 years.

The technological and ecological advantages of supercritical CO₂

Key benefits :

- Low-temperature extraction: ideal for thermolabile molecules (vitamins, essential oils, cannabinoids, active pharmaceutical ingredients...).

- High selectivity: possibility of precisely targeting certain chemical families by modulating process parameters.

- No toxic residues: unlike conventional organic solvents, CO₂ leaves no contaminating traces.

- Circular solution: the CO₂ is 95-98 % recyclable, limiting operating costs and emissions.

- Clean" process: no production of polluting effluents.

Limits and challenges :

- High initial installation costs (stainless steel compressors, exchangers, extractors).

- Complex technology, requiring skills in thermodynamics, fluid mechanics and process engineering.

- Limited capacity for certain large-scale applications.

Applications: a broad, strategic range

Extraction with supercritical CO₂ finds its place in many sectors:

Cosmetics and perfumery :

- Extraction of essential oils (lavender, rose, mint),

- Production of high-quality absolutes with no residual solvents.

Food and nutraceuticals :

- Coffee decaffeination without chemical solvents,

- Extraction of polyphenols, omega-3, natural antioxidants,

- Production of plant- and algae-based food supplements.

Pharmaceuticals and medical devices :

- High-purity extraction of active ingredients,

- Preparation of sterile polymer matrices.

Fine chemicals and materials :

- Processing of polymers and composites (cleaning, doping, impregnation),

- Recovery of toxic or allergenic residues.

Energy and environment :

- Lipid extraction from microalgae to produce biofuels,

- Recovery of residual biomass (wood chips, brewery spent grains, grape marc, etc.).

W Platform, your technology partner

At W Platform, we support industries in setting up circular processes, recovering liquid and gaseous effluents to reduce their environmental impact. Our expertise covers the identification of valuable molecules, the design of appropriate equipment and advice on purchasing and resale strategies for bio-based chemical compounds. Through the know-how, technical skills and years of experience of our team, we have developed cutting-edge expertise in process engineering, chemical engineering and high-pressure systems, which today enables us to support manufacturers in their supercritical CO₂ extraction projects.

This technology, at the crossroads of performance and sustainability, requires a detailed understanding of thermodynamic phenomena, mass transfer kinetics and the constraints specific to each sector of activity. It is precisely this complexity that we know how to transform into clear, effective and appropriate solutions.

If you have a CO2 extraction unit or an extraction, purification or recovery project to explore, our team is here to help you optimize CO2 recycling.

Recent innovations and outlook

Recent research, notably that published in Chemical Engineering Journal and Journal of Supercritical Fluids, show the evolution of technologies towards :

- Multiphase units capable of extracting several families of molecules simultaneously,

- Systems operating at very high pressure (>400 bar), to extend the range of soluble compounds, notably without co-solvent,

- Coupled processes (e.g. CO₂ SC + ultrasound) to improve yields and speed up extraction.

With a view to the circular economy and responsible production, supercritical CO₂ is also increasingly used to cleaning, recycling or reclaiming industrial wasteincluding complex plastics and textiles.

Conclusion

Supercritical CO₂ extraction is not just another green technology: it's a tool for profound industrial transformation. It meets the challenges of sustainability, health safety and technical efficiency. Thanks to its selectivity capabilities and versatility, it paves the way for a new generation of natural, pure and environmentally-friendly products.

Supported by advances in process engineering and growing investment in green industry, supercritical CO₂ is set to play a central role in industrial innovation in the years ahead.

Related articles

See all articles

W Platform gets a makeover

At W Platform, our mission remains the same: to capture, analyze and valorize CO₂ and other gaseous effluents in a circular economy logic. Since our inception, we've grown, matured, rethought our ambitions, and felt it was time for our image to fully reflect our current vision. That's why we're proud [...]

W Platform awarded Young Innovative Company (JEI) status

We are proud to announce that W Platform was awarded official status as a Young Innovative Company (JEI) last May! This recognition marks a key stage in our development, and recognizes our team's constant efforts to place innovation and eco-design at the heart of our projects. Recognition of our commitment to innovation [...].

A credible alternative to 100% hydrogen for decarbonizing industrial activities

While hydrogen is often presented as the cornerstone of the energy transition, its development raises numerous technical, economic and safety challenges. A new technology, based on recycling CO₂ from combustion fumes and converting it into e-fuels like methanol, opens up a simpler, more pragmatic way of accelerating [...]

Transform CO₂ into molecules of interest and produce oxygen for oxy-fuel combustion.

Oxy-combustion is a technology that involves burning a fuel in the presence of pure oxygen, rather than using ambient air. This produces fumes containing mainly CO₂ and water vapor, making it easier to capture CO₂ for storage or recovery. However, the production of pure oxygen is energy-intensive. An alternative [...]

Oxy-combustion: when burning with oxygen opens the way to recoverable CO2

A new way to burn In power plants or cement factories, fuels are usually burned with air. But air is mostly nitrogen (nearly 80 %!). As a result, the fumes contain little CO₂ (only 10 to 15 %). Nitrogen is used as a heat transfer agent, and is therefore not [...]